Finding The Best

Construction Services

Contact Us

Working Hrs : 8.00am to 6.00pm

Working Hrs : 8.00am to 6.00pm

SIP, or Structural Insulated Panel homes integrate a contemporary way to home design and construction that seamlessly represents energy optimization, fast enclosure strategies for the structure of buildings (or envelopes), and unlimited exterior material improvements. SIPs are used for both residential and commercial projects — especially where broadcast capability is important, such as regions that heavily weight energy performance and sustainability. We will discuss the technology of SIPs and its benefits for those considering a house with these methods.

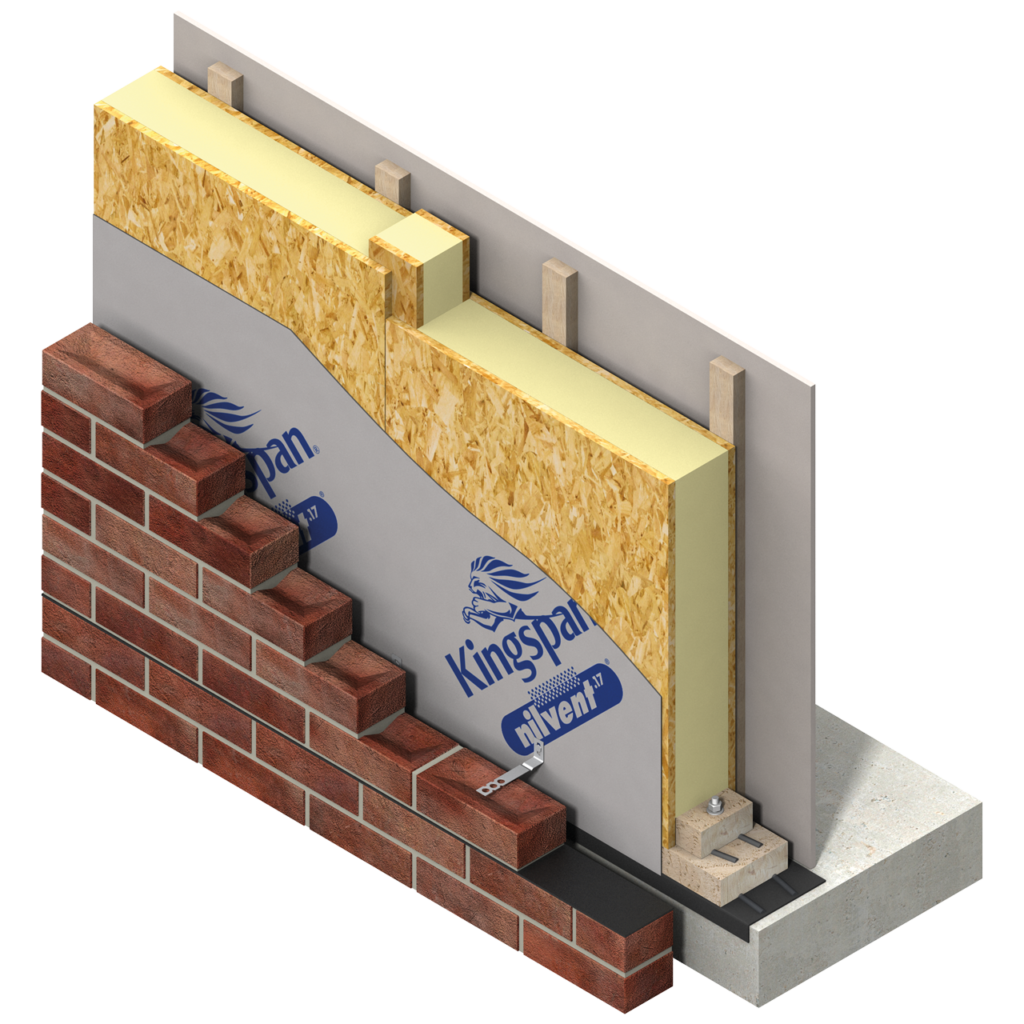

Structural Insulated Panels (SIP) are efficient building materials used in floors, walls and roofs for residential construction. They include an insulating foam core sandwiched between two structural facings, typically oriented strand board (OSB). Made in the factory to meet rigorous standards, the panels are then erected on-site resulting in a robust energy efficient envelope for industry.

Insulation.

The insulating core is most commonly constructed from expanded or extruded polystyrene, and polyurethane.

Structural Facings.

Typically, made of OSB but other materials could also be used based on the job requirements such as Plywood or Fiber Cement or Magnesium oxide board.

SIP Construction Technology.

SIP construction technology places an emphasis on the design of a continuous and solid building envelope which is insulated with air-tight insulating materials. The key aspects include:

Thermal Insulation.

Structural insulated panels or SIP — contain an insulating material to enhance their thermal performance. Unlike other methods of construction, there are no thermal bridges (gaps between the external and internal parts), so this minimises heat loss making it highly energy-efficient.

Structural Integrity.

This creates a very strong composite panel with the rigid foam core and structural facings working in combination. SIPs are capable of carrying the loads for many different types of buildings, even multi-story residential structures. The panels are designed to be wind and seismic ready, so they won’t collapse under stress, even in hurricane-prone regions.

Airtightness.

SIPs are used to form very tight building envelopes—key to energy efficiency and air quality. That airtight design prevents drafts and air leaks from occurring, thereby preserving the indoor temperature, thus diminishing the acclimatization of heating and cooling.

It is normally included in the general SIP building design that proper ventilation systems must be integrated into the building structure to ensure adequate air exchange for a healthy indoor environment.

Precision Manufacturing.

Unlike traditional framing, SIP are made in controlled factory conditions to ensure precisely dimensioned and quality products. This amount of accuracy at the construction stage reduces waste on the construction site while allowing faster on-site assembly, as the panels are pre-cut to installation dimensions.

There are several advantages to building using SIP over conventional construction techniques, making it quite a promising alternative for modern homes and buildings:

Energy Efficiency: Probably the most outstanding advantage of SIP construction is that it offers better energy efficiency. Level of insulation and airtightness is extremely high; hence, this reduces considerably the energy use for heating and cooling and brings down, in turn, the utility bills with a reduced carbon footprint.

SIPs can be used in passive house designs, which are ultra-low energy buildings requiring minimal energy for heating or cooling.

Speed of Construction: SIP enable a fast pace of construction in comparison to conventional methods of building. Since the panels get produced and delivered ready to assemble at the site, they save many hours of on-site labor. Because the procedure for assembling is very quick, it can save both labor efforts and time, resulting in reduced construction schedules, making SIP boards quite ideal for projects having tight schedules.

Strength and Durability: SIPs are highly regarded for their strength and durability. The panels have high load-carrying capacity and can bear loads from snow and wind, thus being used for a range of climates and environmental conditions.

The structural integrity of the SIP also means that building constructions done using this method have a longer life and need lesser maintenance over time.

Design Flexibility: SIP are considered to have enormous design flexibility, as they can easily be made for most architectural styles and designs. The panels are bendable to almost every design, whether it be a complex shape or angle. This offers architects and builders freedom for unfettered expression.

With SIP, open floor plans, vaulted ceilings, and large window openings can be constructed to make interior spaces feel contemporary, very spacious, and wide open.

Sustainability: This style of construction is actually considered one of the more sustainable methods. Most materials used, like OSB and foam insulation, are derived from sustainable sources or are recyclable.

Energy Efficiency: SIP buildings reduce energy consumption and hence greenhouse gas emissions, leading to long-term sustainability.

Comfort and Indoor Air Quality: Because their airtightness closes out drafts and allows for constant temperatures throughout the home, SIP buildings improve interior comfort.

Indoor air quality in buildings can also be excellent, free from all pollutants and allergens found in traditional construction methods, under proper ventilation systems.

While SIP construction has all the advantages, some of the factors that must be taken into account include:

Initial Costs.

It may be said that the up-front cost may be higher than other construction materials since the manufacturing process of SIPs is specialized. These costs are usually offset by energy savings over time and a decreased construction schedule.

Skilled Labor.

Proper installation requires skilled labor that is versed in the methodology of using the SIPS. Working with experienced SIP builders, it is highly important for assurance that the panels will be properly assembled and that the building will perform according to expectations.

Electrical and Plumbing Integration.

This calls for great care in planning and running electrical wiring and plumbing through the SIPs. Although the panels are usually pre-routed for utilities, it is hard to make changes at a job site, and specialized tools may be needed.

Manufacturer.

Choosing the right SIP panel manufacturer is not just about acquiring the materials needed for your project, it’s about partnering with a company that can deliver panels crafted with precision and care, ultimately contributing to the long-term success and efficiency of your building. That’s why S&E Construction Groups partners with leading supplies in UK Kingspan and specifically works with Kingspan TEK® panels.

One such advanced, integrated, and efficient building solution is structural insulated panels. Kingspan TEK® panels have been leading the way in SIP technology with respect to excellent thermal performance, sustainability, and the speed of construction. With their help, be it a new house design or an extension to your current home, using Kingspan TEK panels assures a high-performance and environment-friendly option against the traditional way of building.

What are Kingspan TEK® Panels?

Kingspan TEK® panels are the most advanced SIP—made with a core of rigid urethane insulation sandwiched between two layers of oriented strand board. This makes it a strong and lightweight panel, highly insulated to face the most challenging specifications required for walls, roofs, and floors. The Kingspan TEK® panels excel in such features as thermal efficiency, airtightness, and structural integrity, which make them ideally suited for constructing energy-efficient homes to meet or surpass today’s modern building standards.

1. High Performance Thermal

The Kingspan TEK® panels ensure high performance thermal insulation, which significantly reduces heat loss and thereby minimizes energy consumption for heating and cooling. The panel gives U-values as low as 0.2 W/m²K or better for a comfortable indoor climate while considerably decreasing the energy bills.

2. Speed of Construction

Kingspan TEK® makes construction easier and much faster compared to construction by traditional methods due to its large format, accuracy in the manufacturing process, and simplicity in installation. The panels, prefabricated off-site, offer the ability for rapid on-site assembly, thereby reducing labor costs and shortening construction time.

3. Improved Airtightness

The precision-engineered joints of Kingspan TEK® panels establish a very airtight building envelope, which helps reduce drafts and prevents heat loss. This air tightness assists in delivering energy efficiency and indoor air quality.

4. Structural Strength and Durability

The panels offered by Kingspan TEK® are very strong and capable of carrying high loads without any problem; hence, they can be used for a wide range of building designs, including multistory buildings. The resilience of the panels provides a long-lasting and resistant building that can stand the test of time.

5. Ecological Advantages and Sustainability

Kingspan TEK® panels are manufactured using materials and processes which make them sustainable in nature and, therefore, contribute to lessening the environmental impact. The high thermal efficiency and reduced energy use of SIP houses support this sustainable living also and make it an eco-friendly choice for modern construction.

6. Design Flexibility

Kingspan TEK panels make SIPs that offer huge design flexibility. Their ability to be cut and shaped into various architectural styles and layouts allows for the construction of individual home designs. Internally and externally, they will use the vast majority of finish types to ensure that your home looks exactly the way you want it to.

7. Compliance with Building Standards

Kingspan TEK® panels assist builders in meeting or bettering current in-force building regulations, specifically on thermal performance and energy efficiency. They are especially useful for projects targeting advanced levels of sustainability, such as Passivhaus standards or zero-carbon homes.

Applications of Kingspan TEK® Panels in SIP Houses

Walls: Building strong and insulated core walls that gain the strength to become the backbone structure of a building.

Roofs: Very high levels of insulation and strength make them suitable for both flat and pitched roof designs.

Floors: The solid insulated base improves the energy efficiency of the whole home.

SIP houses are a future for energy efficiency, sustainability, and speed in construction. Equipped with better insulation, strength, and design flexibility, SIPs form the contemporary solution to house building, effecting comfort, durability, and environmental responsibility. If you’re about to build a new home or an addition to your existing one, SIPs will give you a chance for an easy and effective building option. At S&E Construction Group, we work in the sphere of SIP construction with staff competencies in consulting and skillful hands to bring your ideas into reality. Building SIP houses with Kingspan TEK® panels is both wise and very effective in ensuring that the finished home will be energy-efficient, durable, and comfortable. With their superior thermal performance, speed of construction, and design flexibility, Kingspan TEK® panels are an ultra-modern solution to the ever-growing demands placed upon today’s discerning home and independent builders. Whether you need a zero-carbon home or just to save money on energy bills, Kingspan TEK® SIPs guarantee a future-proof option, offering state-of-the-art technology with practical advantages.